The K71-859-00 is an important component of a vehicle, and so too is proper lubrication. Unfortunately, people often get a bit confused in this area. Some think all lubrication is the same and that it doesn’t matter which one you choose. In reality, there are many forms of lubrication and it’s a necessity to find the right one. So, what is solid lubrication, and what advantages does it have?

Understanding Solid Lubrication

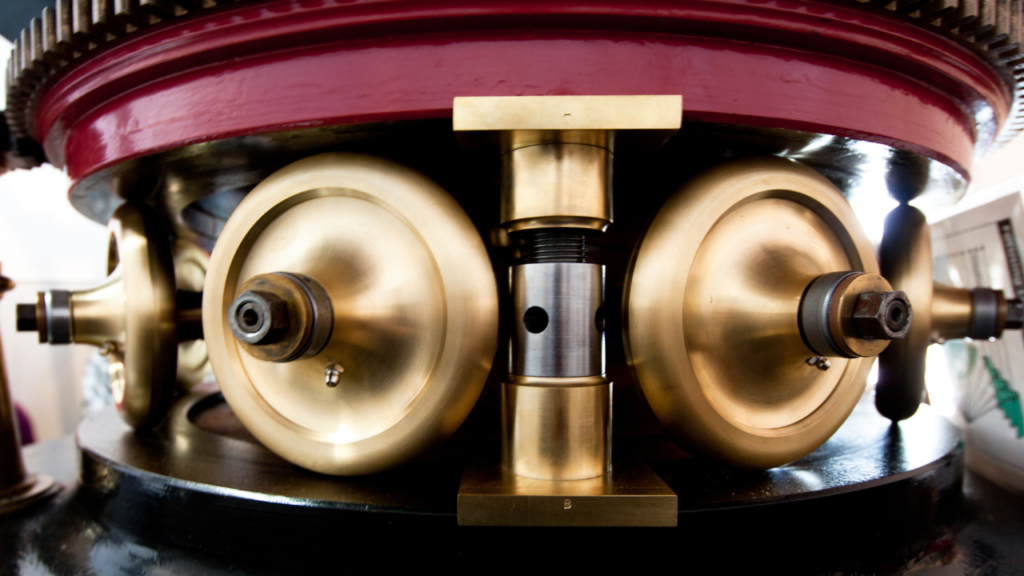

Bearings must be greased (lubricated) to work effectively. Under-lubricating them will result in catastrophic failure and will cost a lot of money to repair. Solid lubrication, however, is a substitute for standard bearing grease. Typically, bearing lubrication is made up of grease, but failures still can occur when it isn’t properly maintained. Solid lubrication changes the process and ensures the bearings last longer and reduces maintenance needs also.

The Process of Solid Lubrication

Solid lubrication is pressed into the bearing cavity which also contains minute traces of oil. This is then released when the bearings are in operation. When the bearings aren’t working, the oil is reabsorbed back into the polymer-made grease. It’s a more effective way of greasing the bearing as it holds more oil than typical grease. Lubrication is most effective here.

Why Use Solid Lubricants?

You need to find what’s right for your vehicle. You wouldn’t replace a K71-859-00 with a cap that’s disproportionate, and it’s the same with grease. The type of lubrication must be effective to achieve the best results. Solid lubricants offer greater reliability. There is also greater protection from the polymer and is easier to work with too.

Why Solid Lubricants are Popular

Contamination is a major problem within an engine. It happens when the greased bearing comes into contact with an unwanted element. It circulates within the grease and may create damage; the severity depends on the extent of the contaminant. Solid lubrication offers greater protection against contaminants. It acts as an extra layer, preventing contaminants from being able to penetrate the seal. This prevents failure from happening. You can read more about How Often Should I Grease the Wheel Bearings of My Trailer? by visiting https://www.pipermotorsports.com/how-often-should-i-grease-the-wheel-bearings-of-my-trailer/

Reducing Liquid Contamination

Water and other liquids can contaminate the grease and get into the bearings. Solid lubrication has polymer materials, and this will reduce how much water gets into the grease. You have a layer or film between the bearing and the escaping oil. This might prevent any failures from liquid contamination.

Using Solid Lubricants

It can be wise to use solid lubrication as a way to protect the bearings and other components. You might also find bearings operate more effectively. This is certainly something that should be given every consideration possible. It can make a huge difference, to say the least.

Make the Switch

In conclusion, selecting the right lubrication for your vehicle’s components, such as the K71-859-00 cap and bearings, is crucial for ensuring optimal performance and longevity. Solid lubrication offers a reliable alternative to standard grease, providing better protection against contaminants and reducing the risk of bearing failures. Just as choosing the correct cargo trailer parts is essential for the safe and efficient transport of goods, proper lubrication is vital for the smooth operation of your vehicle. By switching to solid lubricants, you can enhance the durability of your bearings, minimize maintenance needs, and ensure that all parts of your vehicle, including the K71-859-00 cap, are well-maintained. Proper care and the right components are key to avoiding breakdowns and ensuring reliable performance, whether you’re dealing with a vehicle or a cargo trailer.