Introduction

In the world of trailer components, Dexter has established itself as a trusted name, known for quality and reliability. Among their extensive range of products, the Dexter K71 859 00 holds a significant place. This article puts the spotlight on this particular component, offering an in-depth look at its features, applications, and why it’s a popular choice among trailer owners and manufacturers alike. Join us as we explore the intricacies of this small but crucial part of your trailer’s axle system.

The Importance of Quality Axle Components

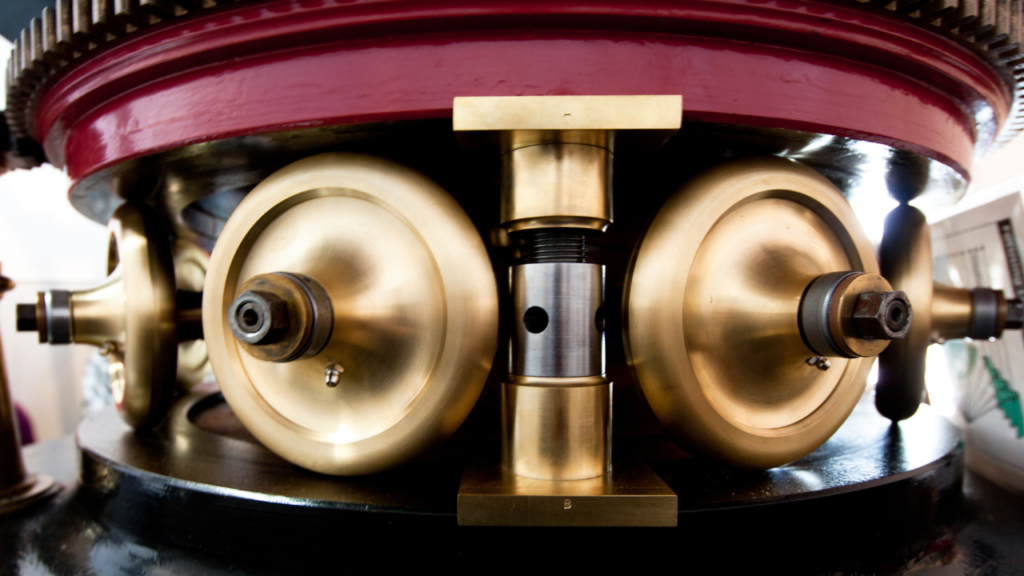

When it comes to trailer maintenance and performance, the quality of axle components cannot be overstated. Axles bear the weight of the trailer and its load, making them critical to the safety and efficiency of the entire vehicle. Inferior components can lead to premature wear, increased maintenance costs, and even hazardous situations on the road. Therefore, investing in high-quality parts like the Dexter K71 859 00 is essential for ensuring the longevity and reliability of your trailer.

Spotlight on the K71 859 00

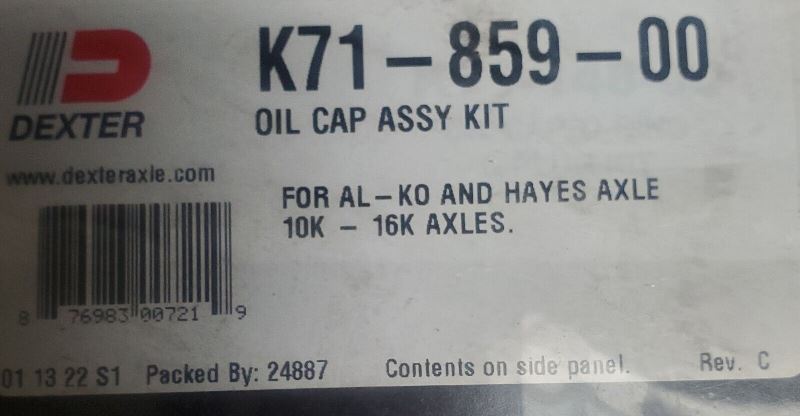

- Product Description and Specifications**

The Dexter K71 859 00 is a replacement oil cap kit designed for heavy-duty axles. This kit includes the oil cap, O-ring, and plug, specifically engineered to fit AL-KO or Hayes axles with capacities ranging from 10,000 lbs to 16,000 lbs. Made in the USA, this kit is a direct replacement for the Alko oil cap kit K568220, ensuring compatibility and ease of installation.

- Materials and Construction**

Dexter’s K71 859 00 is constructed from high-quality materials designed to withstand the demands of heavy-duty applications. The robust construction ensures that the oil cap and its components provide a secure seal, preventing oil leakage and protecting the axle from contaminants. The durability of the materials used in the K71 859 00 means that it can endure harsh operating conditions, contributing to the overall longevity of the axle system.

- Unique Features that Set It Apart**

One of the standout features of the Dexter K71 859 00 is its comprehensive design. The inclusion of the oil cap, O-ring, and plug in a single kit ensures that all necessary components are replaced simultaneously, providing a complete solution for maintaining axle integrity. Additionally, the precise engineering of the O-ring ensures a tight seal, which is critical for preventing oil leaks and maintaining proper lubrication within the axle hub.

Applications and Compatibility

The Dexter K71 859 00 is specifically designed for AL-KO or Hayes axles, making it compatible with a range of heavy-duty trailers. It fits axles with capacities between 10,000 lbs and 16,000 lbs, making it suitable for a variety of heavy-duty applications. Whether used in commercial transport, construction, or other demanding industries, the K71 859 00 ensures that the axle remains well-lubricated and protected from external contaminants, thereby enhancing performance and reliability.

Benefits of Choosing Dexter-Branded Parts

Opting for Dexter-branded parts like the K71 859 00 offers numerous benefits. Dexter is renowned for its commitment to quality and innovation, ensuring that each component meets rigorous standards. Using genuine Dexter parts guarantees compatibility and reliability, reducing the risk of component failure and extending the lifespan of your trailer. Additionally, Dexter’s extensive support network provides customers with the assurance that they can obtain replacement parts and technical assistance when needed.

Conclusion: Why the K71 859 00 Matters for Your Trailer

In conclusion, the Dexter K71 859 00 plays a critical role in maintaining the performance and reliability of heavy-duty trailer axles. Its high-quality construction, comprehensive design, and compatibility with AL-KO or Hayes axles make it an indispensable component for trailer owners and operators. Investing in Dexter-branded parts ensures that your trailer operates safely and efficiently, providing peace of mind and reducing maintenance costs in the long run. For those seeking reliable and durable axle components, the Dexter K71 859 00 is an excellent choice that underscores the importance of quality in trailer maintenance.